智慧倉庫是一個倉儲管理概念. 它是一個 智慧物流 透過IT實現, 物聯網 和機電,以降低儲存成本, 提高營運效率,增強倉儲管理能力. 這篇文章讓你對智慧倉庫有一個清楚的認識

1. 什麼是智慧倉庫英?

智慧倉儲是物流流程的一環. 智慧倉儲的應用,確保倉庫管理各環節資料輸入的速度快、準確. 也保證了企業能夠及時、準確的了解庫存的實際數據, 從而合理地維持和控制公司產品庫存. WMS系統的管理功能有利於 隨時了解所有庫存貨物的當前位置, 有助於提高管理效率. RFID智慧倉儲解決方案還配備RFID通道機, 查詢機, 閱讀器和許多其他硬體和設備.

2. 智慧倉儲的好處

1. 當智慧倉儲設備工作時, 系統自動接收外部訂單以及其他需要出貨的訂單. 在那之後, 設備自動完成相關貨物的入庫和取出過程. 在整個儲存過程中, there is little dependence that the storage on labor forces, which reduces much more labor costs.

2. Automated machines in intelligent warehouses work more efficiently than manual workers and also keep the efficient operation of the warehouse for a long period of time. 同時, 這 smart warehouse system is capable of handling much more complicated work, compared to labor forces.

3. Different from traditional warehouses, intelligent storage can not only decrease labor costs and save human resources but also can be utilized in special circumstances like toxic surroundings, extreme weather and higher-level safety protection needs. 智慧倉儲系統是收集多種先進技術於一體的全新倉儲系統,堪稱倉儲貨架領域最先進的科學技術。

3. 智慧倉儲工作原理

智慧倉儲管理系統的原理因地而異. 不同的工作也會導致不同的工作原理:

1. 倉庫的進出管理: UHF讀寫器將用於倉庫進出管理, 可快速識別物品進出

2. 透過使用 UHF 閱讀器, 堆高機能夠快速、準確地檢測貨物是否需要運輸. 也, 當操作員匆忙工作或有新操作員時,它可以確保物品的準確發貨.

3. 物流車輛的呼叫與分配: 利用物聯網管理物流車輛集中調度,實現運輸效率最大化.

4. 讀寫器用作智慧物流分類系統,可顯著提高效率並確保精度.

5. 使用手持設備檢查產品和管理資產.

4. 智慧倉儲應用了哪些技術

射頻識別

借助採用雷達反射原理的UHF RFID系統自動辨識系統, 讀寫器透過天線向電子標籤發送微波查詢訊號. 然後閱讀器的微波能量可以啟動電子標籤. After the reception of the microwave signal, the reader responds and sends out the echoing signal with the tag that includes data information. The fundamental feature of Radio Frequency Identification Technology is to recognize stationary or moving objects using radio technology, with the purpose of ensuring the objects are identified as well as extracting the objects’ feature information (or identification information).

AGV

With the functions of safety protection and all kinds of mobile and loading transport, AGV is transport vehicles that are installed with automated guided devices that are equipped with electromagnets or optics. These kinds of vehicles can be driven following prescribed guided paths. It is an unmanned transport vehicle that is powered by rechargeable batteries and applied in various industries. An AGV is generally monitored by computers to control its travel route and behaviors, or the route can be established by an electromagnetic track. The movement and operation of the unmanned vehicles are controlled by messages conveyed from the electromagnetic track which is attached to the ground.

The Robotic Palletizer

A pallet stack robot refers to a robot that is able to automatically palletize(or dismantle) goods with different dimensions and shapes on the pallet in a neat way. In order to take full advantage of the area of the pallet and ensure the stability of the piling of goods, the robot has been installed with a sequence setting machine that can control the order of goods for piling. Based on the different palletizing mechanisms, robotic palletizers can be divided into two types: multi-layer type and right-angled coordinate type. It can also be categorized by slide-clamp type, bottom-up dragging type and vacuum suctioning type depending on the different forms of clamps.

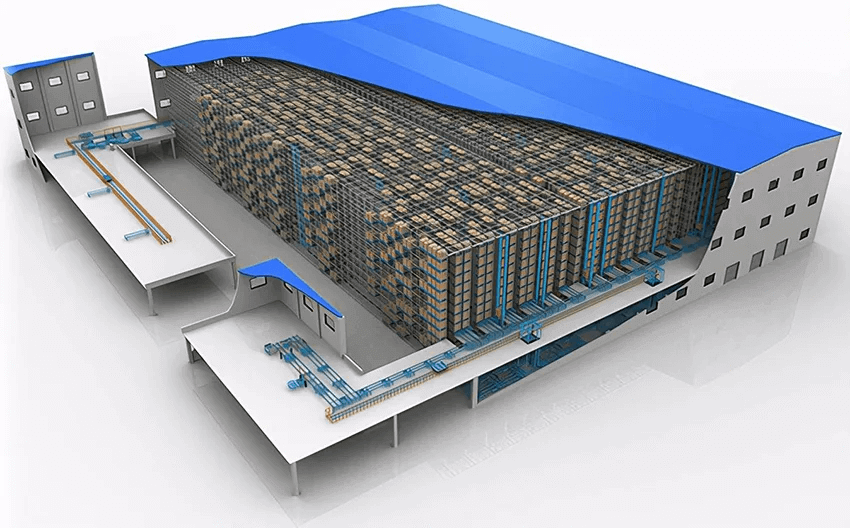

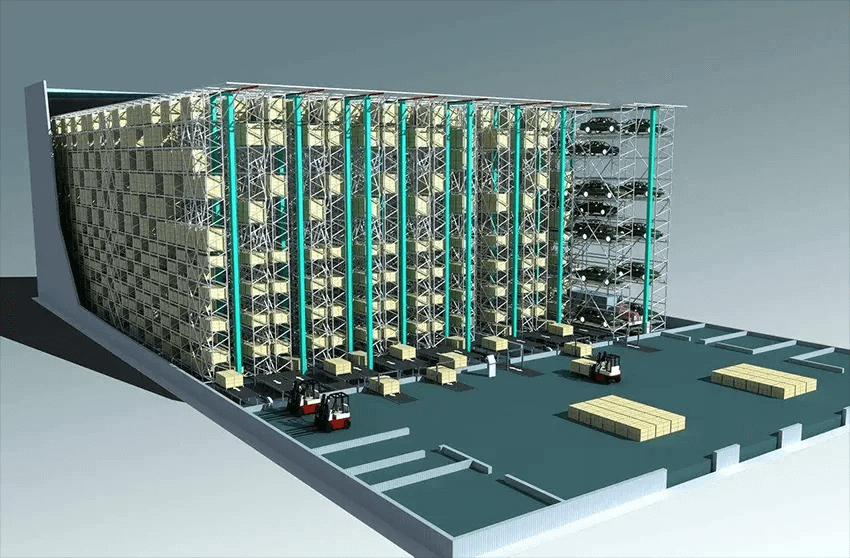

Three Dimensional Warehouse

A three-dimensional warehouse, also known as a high-level shelf storehouse, is called Automatic Storage& Retrieval System (AS/RS). Normally a dozen or even dozens of layers of high selves are included in the warehouse, in which automated transport vehicles handle goods that need to be shipped out and stored. The three-dimensional storage is generally comprised of high-rise shelves, material transport equipment, controlling and management devices, public facilities for land construction, ETC.

Warehouse Management System

A warehouse management system (WMS) refers to an information management system that consists of a series of functions including the warehousing business, outbound business, warehouse management, allocation of inventory management, virtual inventory and so on. Using these functions, the storehouse integrates batch management, material corresponding, inventory check-out, quality inspection management, virtual warehouse management and just-in-time inventory management functions into the information system. A warehouse management system effectively controls and tracks the whole process of logistics and cost management of warehouse business to realize the improvement of warehousing information management. The system can perform logistics and warehousing inventory operations independently, and can also improve the intelligent integration of logistics and warehousing with enterprise operation, 生產, procurement and sales.

Warehouse Control System

The warehouse control system (WCS) is the intermediary between the warehouse management system (WMS) and the logistics devices. The system is in charge of the coordination and schedule of all types of logistics equipment so that the bottom logistics equipment is able to follow up on the business process of the warehousing system. 也, this process is completely executed exactly based on the pre-setting of the program. It functions as a core system to ensure the smooth operation of the entire logistics and warehousing system.

5. 什麼是智慧倉儲系統,什麼是智慧倉儲系統

Smart warehouse system is the result of collaborative work of various interconnected warehousing technologies which creates a technical ecosystem that is able to automatically receive, identify, sort, organize and pick up goods. The well-developed smart warehouse solutions can provide almost the automation of the entire operation from supplier to customer with the fewest errors. You should pay more attention to the traits that help mark a successful smart warehouse system while considering smart storage. Some of these traits are:

Agility

The warehouse control system (WCS) is the intermediary between the warehouse management system (WMS) and the logistics devices. The system is in charge of the coordination and schedule of all types of logistics equipment so that the bottom logistics equipment is able to follow up on the business process of the warehousing system. 也, this process is completely executed exactly based on the pre-setting of the program. It functions as a core system to ensure the smooth operation of the entire logistics and warehousing system.

Scalability

SaaS solutions do not encounter this limitation. Updates can be done immediately, and new content can be rolled out without compromising productivity. Implementing new features simply requires bringing in IT to solve unexpected problems, 智慧倉庫業者想要處理哪些問題.

隨著倉儲和供應鏈變得越來越複雜,智慧倉庫應該能夠跟上未來的變化和需求。智慧倉庫必須為接收大量產品和新產品發布做好充分準備, 這讓我們回到 SaaS 解決方案其他特徵的討論.

如果您已經制定了內部部署計劃, 您可能很難為智慧倉儲系統新增功能. 在某些場合, 更新完成後整個系統可以拆除, 這可能導致系統主要運作速度變慢.

然而, SaaS 解決方案的運作不受此類限制. The update can be completed in time while the new releases can be launched at the same time, which has no impact on the efficiency. Only the introduction of IT is needed to implement new functions so as to tackle new emergencies, which are the actual issues handled by smart warehouse operators.

Data Visibility

As technology continues to evolve, data visibility has become a necessity for most software that is relevant to the functions of supply. This is of great importance nowadays since supply chain and warehousing operations have more complex changes and instant updates as well as data storage, which should be ready for software solutions. Customers and stakeholders tend to be aware of the exact location of their products based on the real-time data provided by the smart warehouse system.

With smart warehouses, interested parties should be allowed to find what they want in a quick manner. If clients have the option of working with an operation that updates data overnight or keeps it up to date, you can help them make the choice.

This is of great importance when taking into account client retention. 另外, data visibility also provides a wealth of useful information for the operation itself. The operator is given a bird’s eye view of the entire warehouse and the performance of individual components according to the real-time data. If inventory or delivery times are inaccurate, you will know immediately where they come from. 在這種情況下, smart warehouse operators can take action before things get under control and put more hands on the job.

6. 智慧倉庫 Examples

Six common application scenarios for Smart Warehousing System

1. Pharmaceutical warehouse: the storehouse of the Pharmaceutical company contains a large variety of drugs, which need to be managed by the system.

2. Machinery manufacture: 3D warehouses of machine manufacturing plants covers a large production area with large amounts of mechanical products.

3. Tobacco warehouse: tobacco warehouses, embracing lots of items, have strict requirements for the environment so using the storage system gives big hands to manage the environment and goods.

4. Military police force: the munitions warehouse of armed police and military, covering large areas with a large quantity of goods, utilizes three-dimensional shelves.

5. Clothing warehouse: it refers to the garment factories used for the production of children’s & adult clothing.

6. Electronic-commerce warehouse: It stands for those storehouses owned by Amazon, Shopify, eBay and other e-commerce enterprises.

7. 智慧倉庫的歷史

Traditional manual storage

Manual warehousing works in a way where much manpower is invested to perform storage management and warehousing works. It mainly relies on the working experience of staff to manage the storehouse. 更重要的是, employees have to go through a long period of training before they are able to do their jobs. 另外, manual storage improves the efficiency of billing records and also reduces the time of making mistakes.

Mechanized storage

During the mechanization stage, the transportation, handling, and management of commodities are no longer purely conducted by manpower but with a combination of mechanical and manual efforts to complete the operations. Items can be transported by conveyors, haulers, cranes, forklifts and other machines. 在那之後, the storage and takeout of goods can be operated by equipment controlled by humans. Mechanical warehousing satisfies various types of needs like precision, quantity, 重量, handling and so on. 然而, as the e-commerce industry and online shopping gain popularity, warehousing and logistics in the mechanization era have faced great pressure.

Automated storage

The transition from mechanization to automation is mainly caused by the growth as well as applications of automation technology. In the 1950s, AGV, 自動貨架、自動倉儲機器人一一普及,在倉儲物流業逐漸廣泛應用, 帶來了倉儲業更高的工作效率. 自那以後, 研發自動辨識系統、自動分類系統,實現機械化向自動化過渡. 1970年代, 旋轉貨架等自動化設備, 移動式貨架、巷道碼垛機在倉儲物流領域廣泛應用,電腦科技對倉儲作業的控制與管理,使得整體效益遠超以前。.

聰明的 貯存

智慧化階段是儲存產業在自動化發展的基礎上進一步研究. It develops towards the direction of intelligence. The emergence of smart warehousing mainly benefited from the growth of artificial intelligence, in which the data between plates and systems can be mutually shared, providing more convenience to deal with work.

8. 智慧倉庫的未來展望

最近幾年, the first echelon of logistics robot enterprises has delivered remarkable achievements. These companies, facing the issues like high renting of warehouses, developed economy, high human resources price and low manual efficiency, are mainly located in typically countries and regions where there are high automation demands of warehousing and logistics. Those countries or regions contain the United States, Europe, 澳洲, 日本, South Korea and so on.

As the back-end link of 智慧製造, smart warehousing and logistics undertake great duties like the improvement of efficiency, customer experience and companies’ core competitiveness with the popular concepts of product diversification and customization. Since the technologies like big data, 物聯網, robots and sensors become more advanced, intelligent storage, functioning as the carrier of the above technologies, is expected to undergo fast growth.

最近幾年, with the growth of the warehousing industry, the ratio of the warehousing industry in the total social logistics cost and the proportion of warehousing in GDP has witnessed a fast rise. And the warehousing industry has played a more crucial role in the overall economic operation year by year. Storage facilities are becoming more and more saturated, and the investment in the industry is turning to terminal node construction, information-based operation and intelligence (cloud storage, 大數據, 物聯網), resulting in a slowdown in the growth of the investment.

With land utilization and labor cost continuing to increase, storage cost has also experienced a significant increase. Cost reduction and efficiency increase are the core tasks in the future development of the storage industry. Developing smart storage, reducing the use of labor and land, and lowering logistics costs will become

the essential tasks that need to be resolved to achieve the development of the warehousing industry in China.