IoT technology is the key technology of smart manufacturing and smart factory, which can be applied to the construction of enterprise manufacturing information systems, equipment integration management, logistics system innovation, supply chain integration and other aspects. At present, many researchers are exploring the application of Internet of Things technology in the industry, and it has had a significant impact on the development of the industry. In the industry, UPS has used transportation tracking technology that supports the Internet of Things to reduce costs and improve efficiency in the supply chain. Follow along to find out!

1. What is meant by smart manufacturing?

The Internet of Things (IoT) is becoming increasingly popular in both the home and the workplace. According to the report, a whopping 79% of US consumers have at least one home smart device. With the growing popularity of the Internet of Things, it is not surprising that manufacturing has begun to use and exploit its advantages. Manufacturing companies have had to adapt to changing economic conditions over the past decade. Fortunately, the Internet of Things gives these companies the tools they need to modernize. However, despite the ongoing digital transformation of manufacturing, not every company is using and taking advantage of the Industrial Internet of Things.

Making the Internet of Things Today, several companies in manufacturing are integrating the Internet of Things into production and supply. Many manufacturers believe that integrating digital devices into production will be beneficial. It just goes to show that the Internet of Things is a very lucrative market for employers and manufacturers. What can the Industrial Internet of Things achieve?

Here are a few things that can be achieved with the industrial Internet of Things:

1. Predictive maintenance

Every year, manufacturing companies around the world spend millions of dollars on operations and maintenance costs.

Most manufacturers are used to a piece of equipment failing during production. You are advised to maintain the device in time.

But what if companies can’t even predict outages before they happen? That’s easy.

With IIoT facilities such as sensors, data and device analytics, manufacturers can easily detect and predict failures before they occur.

2. Monitor the Internet of Things in real time

Manufacturers are allowed to monitor their assets. Everyone involved in the production process can keep abreast of any event or incident.

Manufacturing is speeded up by improving communication in the production chain.

3. Remote management

Manufacturers had to be present in person to assess the state of equipment and machinery. But any manufacturer can now monitor and evaluate devices remotely.

4. Gather consumer insights

IoT helps companies and manufacturers demand patterns. With this, manufacturers can easily spot user complaints and subsequently modify products to improve customer satisfaction.

2. The application of IoT in smart manufacturing industry

From reduced costs to improved maintenance to enhanced security, the Internet of Things offers many benefits to manufacturing. This article delves into some of the best IoT use cases in manufacturing.

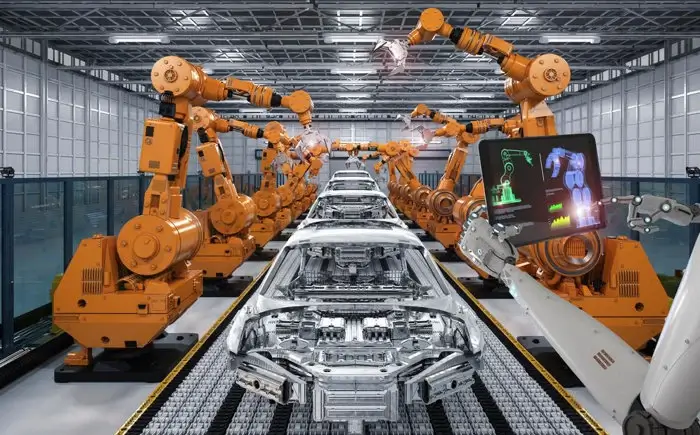

The manufacturing sector is currently undergoing the fourth industrial Revolution and is growing with advances in the Internet of Things, artificial intelligence, and robotics. According to research, manufacturers worldwide will invest $70 billion in internet of things solutions by 2020, and many are implementing IoT devices to leverage sophisticated data analytics and predictive maintenance to increase availability, productivity, and add value to their products.

Companies must understand how these devices transform traditional ways of working into connected and dynamic systems. By leveraging the Internet of Things, IoT sensors can minimize challenges in manufacturing processes and throughout the supply chain.

Improved security

Equipment failures are a key factor in safety incidents, with the study finding that about 151 workers are involved in workplace accidents every 15 seconds. Finally, one of the main ways IoT technology can help secure manufacturing is by saving time. Field data can be transmitted directly to the control room or appropriate area. By implementing AI, data analytics can immediately notify employees of current or pending issues, simplifying the process. By analyzing the data over time, long-term risk indices can be calculated and potentially hazardous situations detected in advance to ensure workers wear protective gear when necessary.

Improved inventory maintenance

It can have a positive impact on inventory maintenance by effortlessly monitoring supply chains and providing businesses with a clear view of moving parts. It allows accurate calculation of supply and effective tracking of products to prevent any stock shortages. With IoT applications such as sensors, alerts can be sent when products are out of stock.

Reduce the cost

Companies are waking up to the potential to save money and boost profits through the Internet of things. Despite the huge cost of implementing the technology, the result, in the long run, is substantial cost savings. It is reducing costs by reducing failures and saving more than 12 percent on repairs. Organizations are enabled to plan better so they can serve customers more effectively. In addition, the ability to implement predictive maintenance results in additional cost savings.

In the future

The Internet of things continues to improve communication and optimize manufacturing processes. Microsoft recently announced that it is teaming up with BMW Group to transform digital productivity across the industry through an open manufacturing platform for the Internet of Things. It is clear that many companies are beginning to leverage this powerful technology, resulting in increased efficiency and a greater understanding of customer behavior needs. Companies will benefit greatly from being trained in the Internet of Things and having in-house staff who are experts in the field, and giving them the right tools to build a better future.

3. The impact of IoT on manufacturing

The integration between the manufacturing industry and the Internet of Things is mainly reflected in four specific aspects: intelligent products, intelligent logistics, monitoring and management of production process and after-sales service management.

Professor Kai Yang, Department of Industrial and Systems engineering, Wayne State University, Detroit, published an article entitled “Hyperlinks — How Ecosystems including the Internet of Things will Transform Product Innovation and Quality” in the August issue of QualityProgress, a respected journal of the American Society for Quality Management.

Among them, the article specifically to Haier of home smart manufacturing practice case analysis as the key, by the clean air conditioning from demand interaction design to the intelligent manufacturing, research and development of the whole process, detailing how the Haier interconnected factory to the user as the center, construct the whole process the user and networking device, three interconnected architecture, realization of Internet of things “hyperlinks” the whole process of the era, quick meet with Personalized customization of the best experience.

From the production of an air conditioner to the customization of clean air

“How to ensure that the air blown out of the air conditioner is clean?” “How do I turn down the air conditioner when I have a new baby?” … In the past, such customer demand could not reach the manufacturing end in the first place. Today, the Internet of Things has changed the relationship between users and producers: mass manufacturing led by enterprises is gradually shifting to mass customization driven by user needs. As mentioned in the article, the self-cleaning air conditioner developed by Haier Zhijia is a typical case of the impact of the Internet of Things on product development.

First of all, in the concept generation stage, Haier Smart home had more than 150,000 user interaction, understand the comfort, health, quiet and other air conditioning needs; At the design stage, designers, r&d personnel and resource side participated in the innovative design, and carried out 5 iterations according to user needs. In the stage of virtual experience, users evaluated virtual products and redesigned them 56 times with designers. 23 technological breakthroughs were achieved in this process. The last stage is the feedback stage, haier Zhijia according to the user 1.5w+ feedback and discussion, continuous iteration of the product. Data shows that the out-of-stock rate of Haier’s connected factory products can reach 72%.

Now, Haier’s connected factory has transformed from mass manufacturing to mass customization, realizing high efficiency driven by high precision. Behind the birth of a self-cleaning air conditioner, the connected factory realizes the “hyperlink” with users in three aspects: first, the whole element of the connected factory, so that users’ orders can be directly placed in the factory, and the production of products can be transparent and visible; Second is the networking device, through user experience information to promote better research and development upgrade and iteration; At the same time, it also integrates the whole ecology. The upstream and downstream of the enterprise as well as all resources should be connected in parallel with users to interact with them at zero distance, so as to meet users’ best experience.

From the manufacturing factory of the enterprise, to the smart manufacturing platform of the whole society

In the context of new infrastructure, more and more powerful devices, components and technologies are entering the smart manufacturing process. Every industrial revolution will cause profound changes in quality management practices, and Industry 4.0 is no exception.

So how will “digitization” change production processes? Under the continuous upgrading of flexibility, digitalization and intelligence, Haier Zhijia officially released the world’s first intelligent +5G interconnection factory in July last year, to redefine the future intelligent manufacturing with the innovation and transformation of enterprise organization, business model and ICT technology, and the deep integration of artificial intelligence, 5G and other key technologies. In Haier’s smart +5G connected factory, when the operator of the production line encounters an emergency difficulty in production operation, he/she can carry out remote real-time audio and video communication with technical experts by wearing AR glasses. Experts at the other end can carry out AR labeling, frozen screen labeling and other operations in real time, and feedback the guidance information to the operator’s line of sight in the first time.

And such application scenarios, with the perfect integration of AI+5G technology, are all over the connected factory. At the same time, through the simulation modeling based on the data validation, precision production efficient coordination, quality control, Haier interconnected factory exploring practice more scenes of iot intelligence products, intelligence combination solution and application of AI technology, realize the production efficiency, manufacturing costs, not RuKuLv capacity indexes such as maximum optimization, the formation of strong competitiveness of manufacturing industry intelligence.

If Haier Zhijia successfully contributed a global brand for China in 36 years, then in the era of Industry 4.0, Haier Internet Factory relying on the industrial Internet platform Kaos COSMOPlat to explore the mode of mass customization, there is no doubt that the “Chinese model” will have the opportunity to lead the era of smart manufacturing.

Development strategies of manufacturing enterprises under the environment of Internet of Things

(1) Correctly understand the impact of the integration of the Internet of Things and manufacturing. Internet of Things is a new Internet technology strongly supported by China, which has a very important impact on the manufacturing industry and plays a very important role in promoting the development of the manufacturing industry. Therefore, enterprises must correctly understand the impact of the integration between the Internet of Things and the manufacturing industry, and actively respond to the new situation in the change, which is conducive to the development of the manufacturing industry.

(2) Promote the application of IoT in the manufacturing industry and develop the informatization construction of enterprises. For self-made enterprises, they must actively promote information construction, so as to promote the integration of Internet technology and information technology, which is conducive to the improvement of economic benefits of enterprises, and also to provide technology and power for sustainable development of enterprises.

The informatization of manufacturing enterprises is a very complicated system engineering, which is beneficial to improve the flexibility and agility of enterprises, enhance the comprehensive competitive strength of enterprises, and realize the leapfrog development of enterprises. Informatization can improve the r&d practice, cost, environment and knowledge content of enterprise products.

(3) The Internet of Things must pay attention to information security in the application process. At the present stage, the control system of manufacturing enterprises generally operates through LAN or private networks. The network itself compares external signals and blocks potential external attacks. Industrial communication tends to put encryption in the second function. In the context of the Internet of Things, many equipment signals need to be realized through the public network, which causes a huge hidden danger to the network of manufacturing enterprises. To ensure information security, first of all, to ensure the security of perception nodes. Second, to ensure customer privacy security and data security. Data collection and transmission are vulnerable to the destruction and theft of illegal competitors, if not fully paid attention to, will bring huge economic losses.

4. Advantages and benefits of smart manufacturing

First, what is smart manufacturing?

First of all, let’s understand what smart manufacturing is.

Intelligence is believed to be the sum of intelligence and knowledge, the former is the ability to obtain and apply knowledge to solve, and the latter is the basis of intelligence.

Smart manufacturing systems and intelligent manufacturing technology compose smart manufacturing. Intelligent manufacturing systems enrich the knowledge base in practice with self-learning functions. Moreover, it also collects and understands information about the environment and itself, and analyzes, judges and plans its own behavior.

The theory and method of multi-agent systems in distributed artificial intelligence are applied to realize flexible smart manufacturing units and networks under the distributed manufacturing network environments.

Second, the benefits of smart manufacturing

After knowing what smart manufacturing is, let’s talk about the benefits of smart manufacturing. There are five main benefits: higher quality, higher precision, better customization and personalization, better forecasting, and better monetization returns.

1. Higher yields

Smart manufacturing uses better control methods to control machine production (including AI, robots, batch control, etc.), which is more efficient than traditional manufacturing. In addition, the application of big data in smart manufacturing can help manufacturers understand the production process more effectively and help improve production operations. Therefore, intelligent manufacturing brings higher output is the main reason.

2. Higher accuracy

In the production process, using methods such as machine vision can lead to more accurate identification. In addition, to reduce the likelihood of failure throughout the production process, traditional manufacturing needs to adopt better equipment and train operators, but reducing failure rates are still difficult. In smart manufacturing, big data can analyze errors and prevent the failure rate caused by errors.

3. Better customization and personalization

Customization and personalization are one of the charms of intelligent manufacturing. The assembly line of traditional manufacturing is difficult to achieve customer customization or personalized customization, while the production process of smart manufacturing can realize real-time control and adjust the production robot according to customer needs, so that it is easier to customize and personalize products. Compared with traditional personal workshops, customization and personalization of smart manufacturing can utilize big data to organize production experience and batch process the customization and personalization it brings, and can also help manufacturers reverse engineer to provide familiar suggestions and solutions.

4. Better forecasting

In the past, manufacturing production was limited by orders. At the same time, it is divided into the low season and high season, high season to increase output, and low season to reduce output. Big data in intelligent manufacturing will make it easier for manufacturers to control their output and make better predictions. Produce under the most valuable production conditions. At the same time, big data can also bring information into the production process. For example, it can track product data from different suppliers to determine the quality of a supplier’s product offerings and thus predict better suppliers. Similarly, big data can be used to anticipate customer needs and make more rational production plans in response to customer needs.

5. Higher profitability returns

Higher output can better meet production needs, higher accuracy can ensure product quality, better prediction can ensure better sales, better customization and personality, and therefore can better expand sales. Using big data from smart manufacturing, we can better understand the efficiency of manufacturing operations. At the same time, we can calculate the return on investment (ROI) of intelligent upgrade and retrofit processes, and the manufacturing industry can better plan for future manufacturing.

5. Challenges and risks of intelligent manufacturing

Manufacturers are leading the way in applying product quality and employee safety. But the shorter time-to-market, stringent quality regulations and increasingly complex products are still issues that need to be resolved.

1. Artificial intelligence talent shortage

AI professionals and experienced data scientists are scarce. An interdisciplinary team of SMEs, ML engineers, data scientists, BI analysts, and software architects is required for AI projects.

2. Technical infrastructure and interoperability

Manufacturing sites usually have a variety of tools, production systems, and machines that may run on outdated software incompatible with the rest of their systems. Plant engineers must determine the best way to connect machines and systems.

3. Data quality

Getting meaningful, high-quality data, clean is essential to the success of AI initiatives, but manufacturing data is often biased, out of date, and riddled with errors, which can be due to a number of factors. Sensor data collected is one example. Historically, factories have been built using many proprietary systems that do not communicate with each other.

4. Real-time decisions

Often, decisions require immediate action within seconds to identify problems before they lead to unexpected outages, defects, or security issues. Rapid decision-making requires real-time prediction services and streaming analysis that allows manufacturers to take immediate action.

5. Edge deployment

There are many potential use cases in manufacturing, enabling manufacturers to filter data, reduce the amount of data and process data locally, and then sent it to a central server in the field or in the cloud.

6. Trust and transparency

People without a background in data science have a hard time understanding how data science and predictive modeling work, and have little confidence in the abstract algorithms behind artificial intelligence technologies.

6. What is smart manufacturing example?

Smart factory is a manufacturing solution that offers flexibility with adaptive production processes and lower costs. Based on automation, this manufacturing solution combines software, hardware and machinery to optimize production processes and reduce unnecessary labor and resource waste.

Tesla gigafactory in Berlin

A better example of a smart factory visualization can be found in the Tesla Gigafactory example in Glenhead, Berlin. The Berlin Gigafactory will open in 2021 with Tesla promoting it as the world’s most advanced mass-production facility for electric cars.

Tesla is committed not only to building smart cars, but also to using smart production methods. Initial photos of the plant released by the company’s chief executive, Elon Musk, depict their vision for a smart factory in which solar panels take up the roof, creating a more sustainable way of production. Tesla’s official website mentions pushing the boundaries of vehicle safety with new dimensions of casting systems and efficient body workshops. Tesla’s relentless efforts to change the way factories operate have allowed them to revolutionize the auto industry.

Adidas Speed Factory, Ansbach

Adidas set up a speed factory in Germany. It focused on the sneaker production process in a single space. They specialize in mass customization that reduces lead times, using 3D printing technology to easily create digital replicas or models. Printing prototypes quickly helps to respond appropriately to changing consumer needs and meet customer needs in a matter of days. Adidas may have gone out of business in Ansbach, but they continue to use speed-factory technology to make sneakers in Asia.

Interconnect Factory, Bosch, Bretia

Global manufacturing of automotive technologies requires increased productivity, and Bosch is doing just that at its leading plant in Brasach. The company implements cutting-edge technology in connected manufacturing, using 20 tablets a day to track processes, check machines and check parts, data that the plant’s 150 machine operators ignore. Bosch’s performance tracking system can detect cycle time deviations of a few milliseconds, enabling operators to respond quickly and intervene early.

Another technology is Bosch’s Nexeed. Developed by the company’s Connected Industry cluster, the software reads data from 60,000 sensors and relays the information to employees in a timely manner. Thanks to these clever innovations, Bosch’s ABS/ESP safety systems produced worldwide have increased productivity by 24%.

Amberg Siemens Electronics Factory

Siemens’ “Amberg Elektronikwerk” (EWA) has won the 2018 Industry 4.0 Award in the “Smart Factory” category. Electronics factories have teams of people, machines and robots that produce SIMATIC type programmable logic controllers (PLCS). The factory has made efforts to achieve full interconnection of machines and products in the factory.

The company relies on industry 4.0 elements to continuously improve productivity and achieve ambitious cycle times. In addition, the capabilities of their MindSphere IoT platform facilitate predictive maintenance by helping plant operators respond prematurely to potential system failures.

Infineon Smart Factory, Dresden

Infineon’s smart Factory facility in Dresden dazzled the world. The factory has achieved 92 percent automation, with more than 200 robots assisting employees. Infineon produces over 400 different products for all four divisions of the Group with high quality and high speed.

The company’s systems control, wafer shipping and production management are interconnected and controlled in real time through IT systems. The transport of wafers is automated and the smart factory is controlled by a central operation and monitoring system and algorithms.

These smart factories are the culmination of the last two decades of a combination of the digital age and ancient manufacturing practices.

7. Smart manufacturing technologies

Intelligent manufacturing combined with advanced information technology, electrical automation technology, artificial intelligence, AI technology, using high-tech intelligence equipment from the factory production of the first line began to build up intelligent production line, building intelligent production workshop, factory building information intelligence, intelligent management, advancing the intelligence services and realize the whole value chain of manufacturing intelligence and innovation.

1. Smart Products

Software, electrical, mechanical, and electrical composes intelligent products. Intelligent equipment is also a smart product. The way to add intelligent units to products should be considered by enterprises.

2. Smart Service

It can sense the status of products for preventive maintenance. Big data of product operation can also be collected to assist enterprises. What’s more, the development of customer-oriented apps is also a way of intelligent service to target users.

3. Smart Equipment

Manufacturing equipment has gone from mechanical equipment to numerical control equipment, can realize in-machine detection, improve machining accuracy, and compensate for thermal deformation.

4. Smart Production Line

Enterprises in many industries highly rely on automated production lines. But equipment manufacturing enterprises are still based on discrete manufacturing. The automatic production lines can be divided into flexible automatic production lines generally established buffer, flexible automatic production lines, and rigid automatic production lines.

5. Smart Workshop

A workshop usually has several production lines. It is necessary to collect and analyze the material consumption, equipment status, production status, production quality, and energy consumption in real time. Hence, MES has become the inevitable choice of enterprises.

6. Smart Factory

A factory often consists of multiple workshops. The production process of the intelligent factory should be transparent, automated, visual and it’s quality inspection and analysis, product testing, production logistics and production process should achieve closed-loop integration. Collaborative operation, on-time delivery, and information sharing should be realized among multiple workshops. Some discrete manufacturing enterprises have also established production command centers. The granularity of MES ProducTIon scheduling is days, hours, or even minutes.

7. Smart R&D

Discrete manufacturing enterprises have applied CAD/CAM/CAE/CAPP/EDA tools and PDM/PLM systems in product development, but e-Works has found that many enterprises do not have a high level of application of this software in the process of providing consulting services to manufacturing enterprises. Enterprises need multi-disciplinary cooperation of mechanical and electrical software to develop intelligent products; It is necessary to deeply establish a virtual digital prototype, and reduce the physical test through simulation; It is necessary to combine simulation technology with test management.

8. Smart Management

Domestic enterprises also regard OA as a core information system. MDM has been deployed in large enterprises.

9. Smart logistics and SCM

Manufacturing enterprise internal procurement, and production are accompanied by the flow of materials; The stacking robot and application of the intelligent sorting system are becoming more and more popular. TMS and WMS are also widely concerned by manufacturing enterprises.

10. Smart Decision Making

Enterprises produce a lot of data. On the one hand, it is the core business data collected from various business systems and business departments. These data are generally structured data. This is the domain of BI technology. Meanwhile, the Enterprise can use these data to extract the Enterprise KPI and compare it with the preset target. Meanwhile, the KPI can be decomposed layer by layer to evaluate the cadres and employees.

8. Smart manufacturing can achieve the whole

Ai in the manufacturing market is anticipated to reach $13.96 billion by 2028.

The manufacturing industry has made significant progress in adopting advanced technologies for manufacturing operations and processes. The manufacturing sector is implementing ai-driven intelligent solutions and services to improve organizational automation and operational efficiency. As a result, there is a significant growth in demand for the adoption of ARTIFICIAL intelligence in manufacturing for smart manufacturing processes that provide decentralized decision-making, optimize logistics and supply chains, improve production outcomes, improve process efficiency and minimize operating costs to achieve smart manufacturing environments.

There are top 10 companies in the artificial intelligence sector in the manufacturing market listed below:

Letters of the company

Alphabet is one of the global pioneers of Internet-based products and services. Computer hardware and software, cloud computing, search engines, and online advertising technology compose the company’s portfolio. Alphabet also offers G Suite to improve the management of various processes that occur in manufacturing due to its collaboration capabilities.

Amazon Web Services

Amazon Web Services offers an on-demand API and cloud computing platform. It focuses primarily on e-commerce, cloud computing, digital streaming, artificial intelligence, and consumer electronics. AWS helps manufacturers transform their manufacturing operations.

Microsoft corp.

Microsoft mainly provides Microsoft Windows OS, Internet Explorer, Edge Web browser, Microsoft Office Suite, etc. Its leading hardware products are the Microsoft Surface line of touch-screen PCS. Microsoft offers connected Field services solutions, smart Supply chain solutions, PTC ThingWorx, Azure Iot ConnectedFactory, etc.

Nvidia

Gpus for the professional and gaming markets and soCs for the mobile computing and manufacturing markets. Its main GPU product line is labeled “GeForce”. Nvidia also provides parallel processing power for researchers and scientists. Nvidia is taking supercomputer performance to the edge with small systems on modules to allow modern neural networks to process data from multiple high-resolution sensors in parallel.

IBM company

IBM functions make and sells hardware and software, and provides a wide range of hosting and consulting services. The company has a diverse and large portfolio of services and products.

IBM is the world leader in enterprise AI and the largest cybersecurity company. It serves businesses and leaders of all sizes in different industries.

Meticulous Research® ‘s report on the projected growth of AI in the current manufacturing market provides some incredible predictions for the industry.

Intel Corporation

Intel designs, manufactures and sells computer components. Intel IT has worked closely with numerous teams to develop a strategy for integrating IT solutions across hierarchies.

Siemens Ag

Siemens manufactures power and energy solutions for consumer products and services, building and driving technologies, energy, mobility, and finance. It also provides market-specific solutions for a wide range of industries.

General Electric

Ge is a globally diversified technology and financial services company with products and services ranging from power generation, aircraft engines, home appliances, and water treatment to medical imaging, industrial products, and commercial and consumer finance. The company has diversified its business into renewable energy, healthcare, power, oil, and gas, lighting, transportation, and aviation.

Rockwell Automation

Rockwell Automation manufactures information solutions and industrial automation worldwide. The company serves the home, food, beverage, personal care, life sciences, automotive and tire, mining and metals, oil and gas industries. It is divided into architecture and software and control products and solutions. The Architecture and Software division provides control and information platforms.

Advanced Micro Devices, Inc.

Advanced Micro Devices specializes in semiconductor devices used in computer processing. It offers video and multimedia products, microprocessors, graphics, embedded microprocessors, and chipsets. In addition, it serves OEMs, data centers, OEMs, systems integrators, distributors and plug-in manufacturers.

9. What is the market for IoT manufacturing

Digitization of manufacturing helps increase productivity and growth, reduce operating costs and improve products and services. IIoT plays a crucial role in this manufacturing revolution. However, the global iot deployment process is also being challenged by the pandemic and some social factors.

A study in the United Kingdom assessed 2021

Internet of Things adoption in key vertical markets. The survey polled 500 senior IoT decision makers and implementors in the UK and US, 100 of whom work in manufacturing.

How much equipment is there in the plant and on-site?

There are only 5% of manufacturing respondents said they deployed between 10,000 and 100,000 devices. Only 2% of companies deploy more than 100,000 devices. This is significantly lower than healthcare and medical devices, which is lower than smart vending (9 percent) and supply chain and logistics (14 percent).

More than 58% of manufacturing respondents reported deploying fewer than 5,000 devices. Smart manufacturers can benefit from Industry 4.0 and even move towards Industry 5.0.

Core challenges facing manufacturing markets

Maintaining equipment manually is expensive

Experienced engineers are required to monitor the equipment and go to the site to solve problems.

Automation

Essential to improved performance and cost savings. For companies to grow and remain competitive, they need to automate and optimize their production processes.

Real-time data

It is very essential to solve problems effectively. Data analysis and experience can facilitate predictive maintenance.

Connectivity is critical

Many manufacturers operate multiple factories and require reliable connections between factories and the cloud for data storage and analysis.

Equipment needs to be simple and easy to use

The equipment must be easy for engineers to install and operate due to the potential for large-scale deployment.

Security is critical as the gap between OT and IT Narrows. A high degree of security for IoT devices is critical.

Looking ahead — What’s next for the Internet of Things in manufacturing?

Eighty-five percent of manufacturers say IoT is a priority for their business over the next two to three years.

Almost all respondents (93%) plan to increase their IoT budgets.

It will become an important value driver for manufacturing in the future, and companies will continue to increase their IoT deployment budgets as market expectations increase.