IIoT is applied in industrial operations such as industrial production, medical, and surveillance, bringing higher efficiency to industrial production. The development of big data in the modern age has strengthened our connection. The data of the items can be collected, stored, and analyzed once it is connected to the network via the Internet. IoT covers various fields from sports products to smart homes. The Internet of Things is also gradually infiltrating the industrial field. Therefore, the term “Industrial Internet of Things” was born.

1. What is the Internet of Things?

IoT has the abilities of intelligent perception, reliable transmission, and intelligent processing. IoT has been applied to agriculture, logistics and security, and some other areas. The development of IoT has effectively promoted intelligent development, especially by making non-renewable resources to be more reasonably used, and distributed. The Internet of Things has also been applied in fields closely related to people’s lives, such as home furnishing, education, health care, tourism, etc., which has greatly improved the service quality and basic equipment of these industries, greatly Improving the quality of people’s life.

2. What is the Industrial Internet of Things(IIoT)?

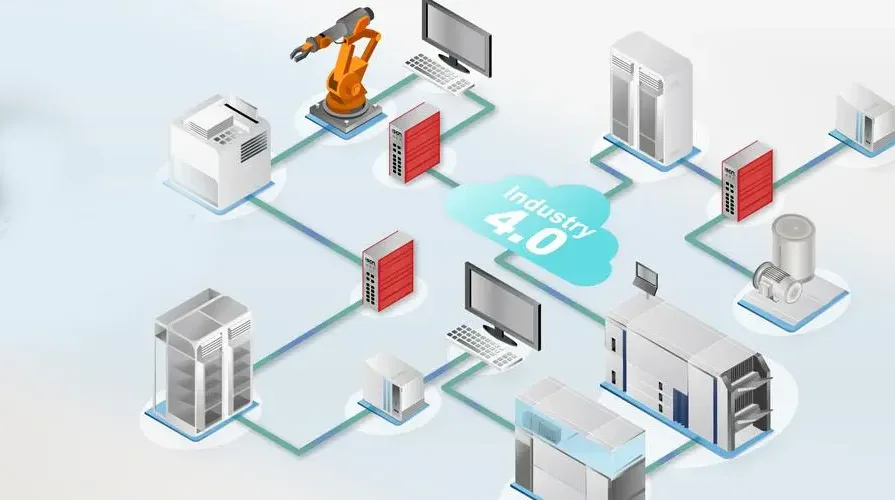

Benefiting from cloud computing, big data and artificial intelligence technologies, the Industrial Internet of Things has ushered in a new development. In recent years, some countries with advanced technology have launched a series of strategies to promote the development of the Industrial Internet of Things, such as China’s smart manufacturing and Germany’s Industry 4.0 strategy. The Internet of Things is applied to all aspects of industrial research and development, production, operation services, etc., to realize the digital transformation of enterprises. People gradually realize the huge value brought by the new business model driven by data, so they have determined to build a service-driven new industrial ecosystem.

3. What Differences between IIoT and Industrial IoT?

Security

Security is critical to IoT, especially the Industrial IoT, which requires strong security guarantees. Unsafe measures in the industrial production process will cause serious damage to the economy, and even threaten the safety of people’s lives and property.

Therefore, major enterprises should pay attention to the security construction of the Industrial Internet of Things, and use measures such as threat detection, authentication, and encryption to ensure the security of production and improve production efficiency.

Interoperability

When evaluating IIoT technologies, a key criterion is an interoperability or the ease with which information is passed back and forth across the boundaries of the technology. Interoperability also includes collaboration between production equipment, the collaboration between production equipment and digital products, and collaboration between digital products.

Scalability

For more complex internal infrastructure, strong scalability means directly improving configuration and facilitating operation and management, which is conducive to adding new resources.

Precision and Accuracy

Among the Internet applications in various fields, industrial IoT applications have the highest requirements for accuracy. Automated mass production requires the IoT system to accurately grasp the small changes in the production process, and to make timely corrections and adjustments based on the detected information. If the accuracy is not guaranteed, it will lead to low production efficiency and even serious economic losses. Therefore, high accuracy is an important factor to ensure industrial production.

Programmability

Traditional industrial processing equipment and processing systems can be programmed and reconfigured to support new processes and new systems. And programming can be operated remotely or on-site. Therefore, IIoT solutions that help industrial production should provide the same or better flexible programmable systems to support operations.

Low latency

In all aspects of production, time is a crucial factor since every second counts. Therefore, systems such as IoT sensors used to monitor production should have the characteristics of low latency and timely report abnormalities detected in the production process. Minimize threats to worker safety due to delays and avoid costly costs and loss of quality.

Reliability

As we all know, one of the characteristics of industrial equipment and industrial systems is the long running time and high frequency of use. Some equipment in the factory may stay in a remote corner and run non-stop for years or even decades. Moreover, these devices may also experience extreme temperatures, high pressures, high vibrations, and other factors. Therefore, IoT solutions used to monitor industrial equipment systems should also have the same reliable operation capabilities to support industrial equipment operating at high intensity in complex environments.

Elasticity

From lost sensors to lost connections, IIoT systems and architectures must compensate for failures in use and still perform their processes and operations satisfactorily.

Automation

Modern industrialized processes are highly automated, reducing the cost of many human interventions. Therefore, the Internet of Things applied in the industrial field should also need to meet the needs of automation. Even edge devices need to be smart. In addition, IoT systems must be programmable and need to complement both old and new execution systems.

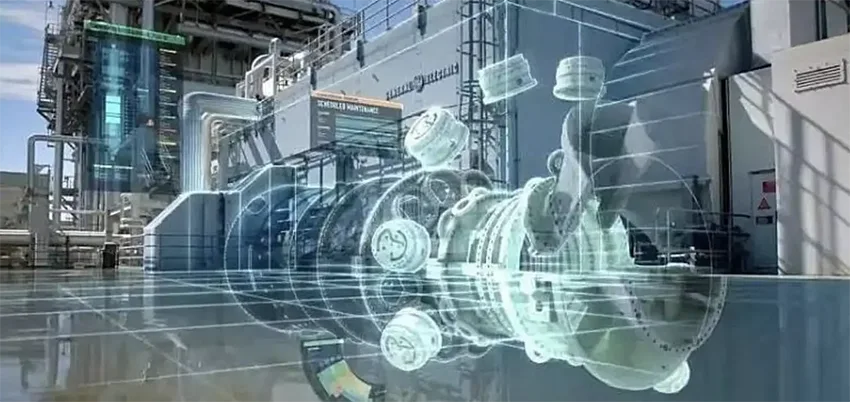

Maintainability

The environment in which industrial equipment operates is relatively complex, and the market is subject to high pressure, extreme cold, or extreme heat. So the maintenance of equipment should be paid attention to, and regular maintenance by internal and on-site technicians is required. The Internet of Things solution applied to complex industrial fields needs to be able to maintain the performance of the equipment.

4. Is the IIoT classification of the Internet of Things?

The IIoT is a branch of the IoT. They also use technologies such as cloud platforms and sensor data analysis, but they serve different purposes. IoT can be applied in many fields including healthcare, enterprise, government, and cities. And Industrial IoT is used to connect machines and equipment in industries such as petroleum, manufacturing, and services. IIoT system failures can threaten life and property and lead to high-risk situations. Compared with user-centric IoT applications, Industrial IoT applied to industrial equipment needs to focus more on security performance.

5. The relationship between the Industrial Internet of Things and the Internet of Things

The Internet of Things is a network that connects things with the Internet. It can exchange and communicate information according to the agreed protocol. It is the kind of network that can realize intelligent identification, tracking, positioning, and management. Generally speaking, the IoT means is “the Internet of things connected”.

By using intelligent technologies such as actuators and smart sensors in industrial areas, efficiency has been improved and the cost has been reduced greatly, this process is also called the realization of the Industry Internet of Things. The introduction of IoT in industrial areas is revolutionizing traditional industry, creating a new experience for enterprises and workers.

The IIoT is also known as Industry 4.0. It has great potential for quality control, beneficial to sustainable and green practices.