The purpose of this article is to give you a comprehensive concept of what IoT asset management is. A McKinsey study found that supply chains have incorporated technologies such as big data analysis into 43 percent of processes, which they call “digitalization.” With the reduction of the overall cost, and the improvement of customer satisfaction with digital technology, people’s recognition of it continues to rise, so this number is expected to continue to rise. Using IoT technology for asset management will greatly reduce costs.

1. What is IoT Asset Management

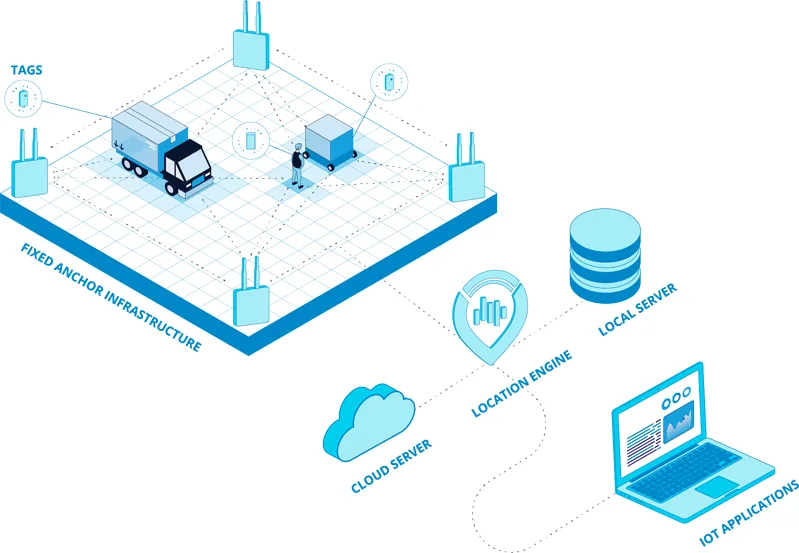

As the Internet of Things technology becomes more and more mature, the Internet of Things has spawned a steady stream of development power for asset management. Comprehensive perception, interconnection, and intelligent processing are the distinctive features of the Internet of Things era, which are also the mainstream direction of current asset management methods. To strengthen the management and supervision of assets, innovate asset management methods, and create a new platform for intelligent, perceptual, and interconnected asset management, Guozi Software combines years of industry experience, and at the same time deeply integrates IoT technology, with the help of the identification, positioning, tracking and monitoring features of IoT technology, effectively solve the problems of asset dynamic supervision, inventory, safety management, performance assessment, and sharing in the process of asset management, realizing intelligent dynamic supervision of assets.

2. How is IoT Used in Management?

01. Establish business standards

Manufacturers must establish the following metrics and benchmarks in advance if they want to get the benefits of digitized supply chains

● Real-time indoor and outdoor locations of goods

● Handling of Goods (such as handling, temperature, and humidity)

● Destination Distance and Trip time

This data helps identify areas for improvement and key performance indicators that are aligned with business goals.

For instance, a carton supplier implements an IoT solution to shorten the turnover time from the warehouse to the wharf. Employees will first walk through the entire warehouse and then use bar codes to scan the collected packages for shipment. Real-time monitoring of package condition and location on site and in transit is important to optimizing solution efficiency

02. Identify important data sources

After the business standards are established, the next step must be to identify important data sources and equip them with smart labels. Such as temperature, GPS, humidity and pressure sensors, and some other labels. Identifying labels in advance is important because too many labels may generate too much data and waste time sifting, while too few labels may provide too little data to use.

For example, a small to mid-sized vegetable distributor that wants to keep an eye on the freshness of a variety of vegetables from the warehouse to the individual retailer may only need to place a smart label per vegetable category.

03. Accumulate and summarize data

With the identification of key data sources and the marking of smart labels, all real-time data needs to be aggregated into the IoT gateway. Depending on business needs, these gateways may be located in warehouses in the supply chain, on vehicles, or both. They analyze real-time data from sensors and extract and store the required data points, such as speed, temperature, and pressure.

Some complex supply chains need to be equipped with more data processing due to their additional business requirements. When sensors send data to IoT gateways distributed across multiple warehouses and fleets, these data will need to be pushed to a secure cloud for processing.

04. Develop visual and analyzable applications

Collected and processed data is only valuable if it can be transformed into clearly visualized business analytic material. The best way to achieve this is to develop applications with visualization and reporting tools, such as mobile and web control panels.

05. Preemptive automation

The supply chain should strive to start and run the IoT asset management solution as soon as possible. Once the solution is applied, many problems in the supply chain can be solved through automated analysis and reporting. This automation can significantly reduce labor costs and operational risks, especially in complex 24/7-365 operations.

If the smart tag sensor reports that one of the seafood distributor’s trucks is warmer than average in transit, it sends an alert to the driver’s mobile device.

In the end, it’s important to remember that digitization is more about steady movement than hasty activism. It is best to start modestly and then move on after determining which solutions and processes work best.

3. Advantages and benefits of IoT asset management

01. Real-time data acquisition

IoT technology enables ordinary business devices to be “location-aware”. The real-time location of these commercial devices and their usage information can be sent to other computer systems or related personnel in time. As the cost of real-time data collection technology falls, it puts data collection capabilities previously only available to large enterprises into the hands of small enterprises, enabling organizations of any size to derive business value from this technology.

02. Automation

IoT asset management systems automate supply chain systems, streamlining tasks that would otherwise be labor-intensive and error-prone. For example, transaction record management used to take an asset manager’s entire day, but today these tasks can be automated with IoT asset management

03. Optimized asset usage

IoT asset management systems allow for more granular control over how equipment is used and maintained. For example, you can optimize the use of warehouse equipment by rotating it to even out wear. Leverage IoT and data analysis to make significant improvements to key operations, and gain insight into the future through monitoring and optimizing the maintenance of what’s happening today.

04. Performance and usage monitoring

IoT asset management enables you to track asset and equipment usage in real-time and provides you with the cost and usage of existing inventory equipment. This insight can influence future buying decisions. For example, tracking data may show that one type of printer is damaged several times as often as another. In the next fiscal year, you have the option to replenish your inventory with a better-performing printer.

05. Workflow support

The use of IoT asset management systems enables new and convenient business processes and workflows. For example, you can specify maintenance lockers in an equipment storage system. If a piece of equipment is damaged, the system can automatically notify a technician to repair it. The user will then be prompted to store the damaged device in a fixed location to prevent it from being used any further

4. What are the types of IoT asset management?

The industries to which the Internet of Things platform is applied generally have a part of the five core elements of the Internet of Things, the core elements can be said to be the digital resources of the company, that is, assets!

01. Companies in the communications field

It belongs to the type of “connected asset” enterprise, whose core asset is to provide extensive and comprehensive connection and take connection service as the core business service. Therefore, on some occasions, the Internet of Things platform in the field of communication will be referred to as the CMP platform.

02. Enterprises in the Internet field

It is a “user data asset, computing asset” enterprise (its data is oriented towards users and Internet applications), and its core assets are the retention of a large amount of product and user application data, and they also the ability of cloud computing (big data and artificial intelligence). Combined with Internet-based intelligent products, it provides application enabling services and analysis functions in computing services, which are the business core services of the Internet of Things platform.

03. Companies in software/system services and verticals

They belong to the “industry data asset” type of enterprise. On the one hand, they also have a lot of data (production data, including parts quality data in the production process). On the other hand, they have rich experience in industry technology, production management, and software development, and use application services and computational analysis functions as business core services

Some people in the industry believe that the IoT applications of many enterprises in this field are mainly “customized”. Compared with enterprises in the Internet field, the openness of the IoT platform is slightly lower, and there may be a lack of market momentum in the future. However, in the early stage of IoT development, the “tight coupling” of the development capabilities of enterprises in this field is the guarantee of maximizing the efficiency of IoT projects.

The up-down system integration can effectively solve the problem of heterogeneity among information systems of the Internet of Things, concentrate on obtaining the business value of the Internet of Things, and push the Internet of Things platform to a “loosely coupled” and highly open service state.

5. What technologies are used to track assets in the Internet of Things

LBS positioning technology has the characteristics of holographic positioning and precise control, provides indoor and outdoor global positioning solutions, full-time recording of position, dynamics, and trajectory, and supports remote inventory and inspection.

IoT technology, based on GPRS/NB-IoT technology to achieve wireless network connection, can adapt to complex scenarios, and report asset status holographically.

The intelligent sensor idle sensor has a built-in vibration sensor and temperature sensor, which continuously senses the usage of assets, shares idle assets, and maintains frequently used assets.

Big data analysis visualizes data such as usage rate analysis, idle prediction, abnormal statistics, etc., saves expenses, increases efficiency, supports decision-making with data, and helps enterprises in intelligent management and scientific decision-making.

6. Internet of Things Asset Management Solutions

01. Asset management software

For a smooth operation, many companies have begun to use professional asset management solutions that allow each employee to easily access and update asset information. Using asset management software to manage assets, usually means that the company’s assets are tagged by QR codes, bar codes, NFC tags, etc. Asset labels can be scanned by mobile devices that act as a link between the physical asset and its database information.

Trackinnos is a professional asset management solution that provides real-time updates of asset-related information: such as where the asset is, its condition, who is using it, user manuals, etc. You can view and update everything with just a few taps on the screen of your mobile device. A good asset management solution can also send you notifications about changes in asset status or expiration dates for asset usage.

Professional asset management solutions offer a huge improvement over traditional manual methods, but what can the Internet of Things bring?

02. IoT asset management: Automation and Intelligence

Not only asset management software can bring many conveniences to enterprises, IoT asset management solutions also have the characteristics of automation and intelligence. This system solution provides significant cost savings by using sensors to autonomously track specific information about its assets without any human involvement. At the same time, these IoT sensors can be directly connected to assets without applying traditional asset tag (QR code for example) connections.

There are temperature, humidity, acceleration, pressure, and other sensors. Sensors are typically attached to assets in order to collect data, which is then pushed to a cloud platform. Depending on user settings, this push occurs at a specific frequency (every 15 minutes for example). After that, the cloud platform analyzes the data and converts it into visual analysis materials about asset usage, location, and so on.

7. Application examples of Internet of Things asset management

IoT asset management solutions turn automatically-collected data into visual insights that can provide companies with real-time alerts, analyze forecasts, and report data.

Below are some use cases to help you better understand IoT asset management applications

● Location: Asset tracking and automatic location; geofencing solutions (e.g. utilizing GPS trackers)

● Usage time: Automatically tracks usage time and alert notifications of thresholds (for example, acceleration sensors, and temperature sensors).

● Warehouse inventory: Automate warehouse inventory management (for example, BLE beacons).

● Material Flow: Automatically track and report material flow (for example, RFID tags).

IoT asset management usage is often limited to tracking expensive and heavy equipment (trucks, containers, etc.) due to limitations in the size, price, and lifetime of sensor devices. However, technology is constantly evolving, which will allow us to use IoT to track smaller and cheaper devices in the near future.

8. Internet of Things asset management system software

Samsara

Focusing on the Industrial Internet of Things (IIoT), Samsara has a variety of popular asset tracking devices that allow customers to track in real-time through regular check-ins. Through sensors and cameras, Samsara collects vast amounts of operational data generated by fleets, machinery, and remote equipment and aggregates it into a cloud computing platform. As a result, customers can more easily track the progress of operations and make better decisions based on data

Omnitracs

Omnitracs mainly provides a complete set of fleet tracking services, including driver information, fleet telematics, vehicle performance monitoring, etc.

Hilti ON! Track Asset Management

The solution is designed to help the company’s customers replace manual processes with real-time automation, eliminating inefficient and error-prone manual processes. This allows customers to assign the right equipment to the right location at the right time, optimizing the use of assets

AT&T Fleet Complete

Connected via LTE-M, AT&T Fleet Complete is a low-power wide-area network technology that captures GPS information and other data such as humidity, pressure, light, and temperature. Since the system uses solar energy for charging, it is especially suitable for monitoring in industries such as mechanical materials, medical supplies, packaging supplies, etc.

Azuga

As a fleet tracking specialist, Azuga also provides sensors to track small devices and physical assets such as shipping containers. AZUGA sensors use cellular technology and GPS positioning systems. At the same time, its battery can be recharged and recycled, and it can last for six months after each charge. Azuga also provides a geofencing feature that lets you draw an invisible line around an asset and be alerted when a marked item leaves a designated area.

Keeptruckin

Specifically designed for the shipping industry, Keeptruckin’s asset tracker can operate continuously by connecting to a trailer’s power supply or charging using an integrated solar panel. Sensors use a cellular connection to report location and other statistical data to cloud computing software, which can be accessed by users

EROAD

EROAD provides comprehensive fleet management, applying 4G-connected trackers to synthesize asset tracking, with the collected data provided to a single dashboard. The EROAD tracker battery can be recharged and cycled to last six months per charge, or the unit can be run on 12 or 24 volts

ATTI

Advanced Tracking Technologies Inc. (ATTI) provides standard GPS fleet tracking services that monitor vehicle location and usage, fuel consumption, and potential maintenance issues, all of which help increase productivity and efficiency. ATTI’s tracking devices use relatively easy-to-install hardware and utilize the largest cellular and satellite data networks to ensure adequate coverage

Asset Monitoring Solutions (AMS)

AMS’ core business is to provide fleet management solutions. Their company’s tracker uses a multi-network roaming SIM card to provide a reliable cellular connection. Most of AMS ‘trackers are powered by moving vehicles, but a few are powered by lithium and/or rechargeable batteries.

Particle

The particle tracking system can support real-time asset position monitoring. They analyze real-time data from sensors and extract and store the required data points, such as speed, temperature, and pressure. Their trackers use different technologies on different continents, such as LTE Cat-1 with 3G/2G fallback in Europe, Asia, and the Middle East and Cat-M cellular technology in North America.